- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

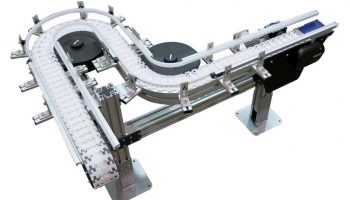

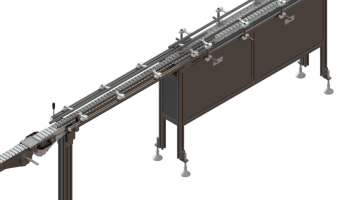

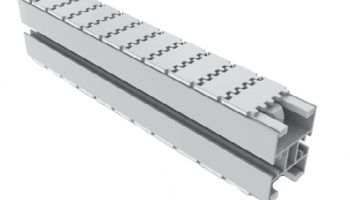

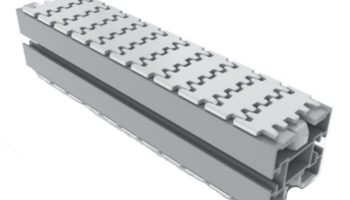

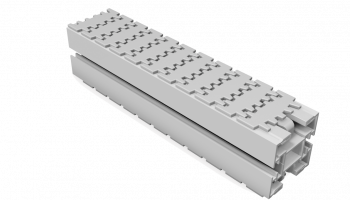

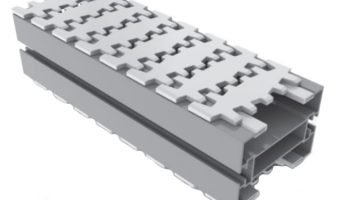

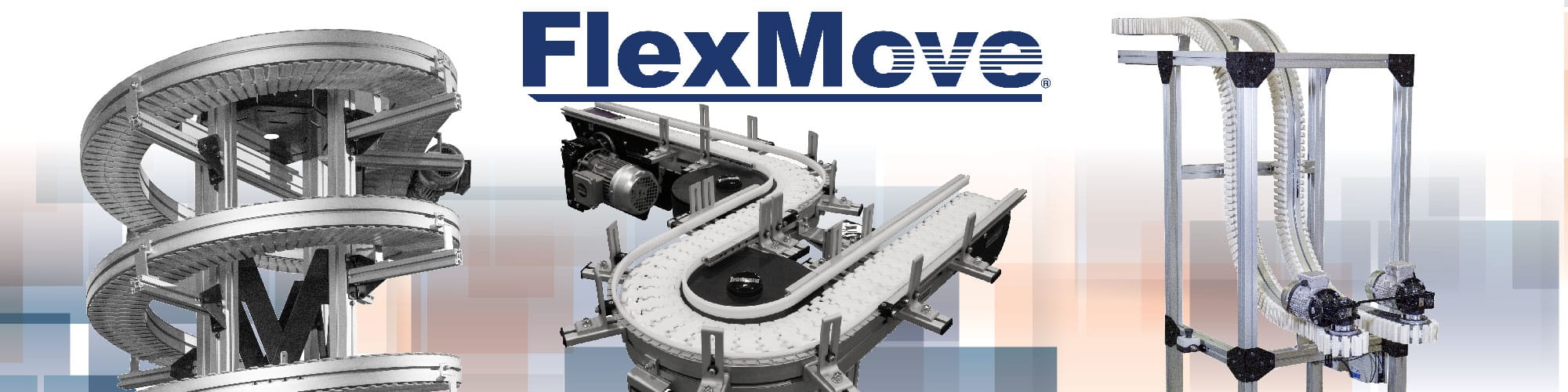

Flexible Chain Conveyors

Features & Benefits

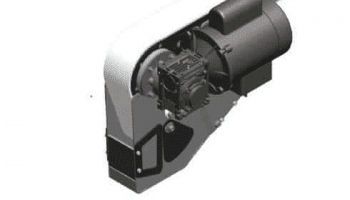

Dedicated to high quality, innovative designs, and comprehensive conveyor platforms, we deliver products equipped to accommodate virtually any material handling application and provide efficient solutions for a wide range of manufacturing industries.

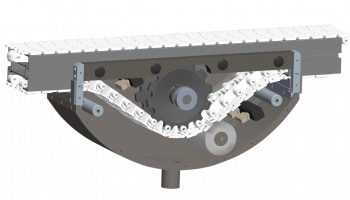

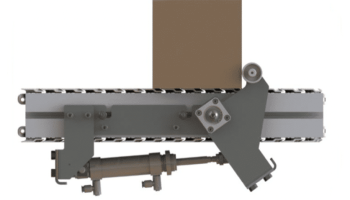

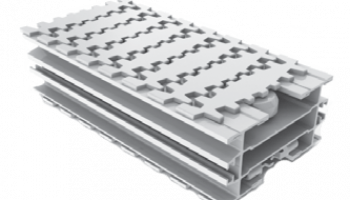

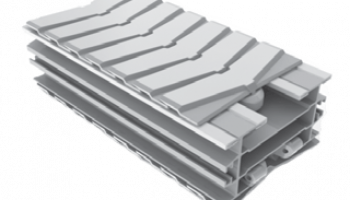

To further help your business transport a broad range of products, FlexMove Conveyors offer a variety of options with unique features, such as flexible chain with cleats, rollers, friction pads, steel top, and anti-static.

Benefits

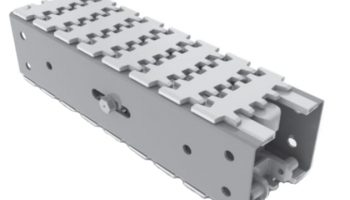

- Easily customized and reconfigurable system.

- Industry’s most flexible plastic chain belt, capable of multiple turns and inclines in one line.

- Low-profile design is ideal for tight spaces.

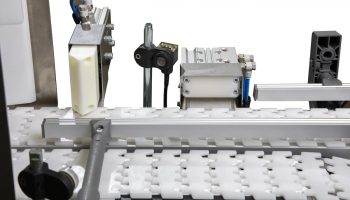

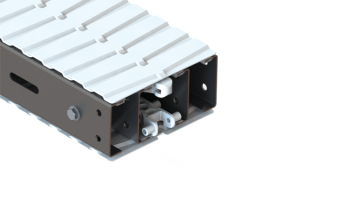

- Easy integration with controls, photo-eyes, sensors, and more.

- Variety of modules and belting options available to meet a wide range of application needs.

Specifications

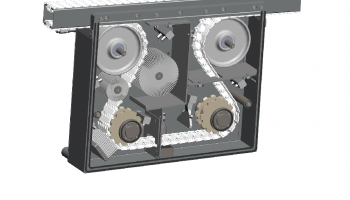

- Wide variety of chain types including low friction, friction inserts, cleated, conductive, and more!

- Widths: 45-260 mm

- Legths: 0.6-30 m (2-98 ft)

- Loads up to 272 kg (600 lbs)

- Speeds up to 76 mpm (250 fpm)

Specifications may differ for each FlexMove Solution.

FlexMove Product Lines

FlexMove conveyors are available as completed conveyor systems for fast and simple, installation, or as parts for flexibility in design.

Complete conveyor systems shipped in sub-assemblies for fast and easy installation

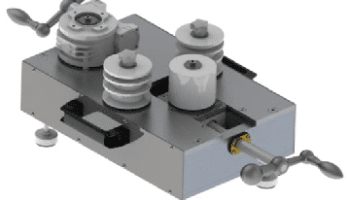

Accessory modules designed to enhance the abilities of FlexMove conveyors.

Aluminum and Stainless conveyor components for complete flexibility in layout and design

Industries & Applications

As one of the most versatile conveyor systems available, FlexMove conveyors are the perfect solution for many different applications from indexing and sorting to packaging and inspection. With easy integration features and a completely customizable design, our FlexMove systems can be configured to meet the exact needs of almost any operation, including:

- Part Handling

- Transfers

- Tight Spaces

- Assembly Automation

- Packaging

- Machine Conveyance

- Elevation Changes

- Accumulation

- Buffering

- Complex Configurations

- Long Lengths

- Curves, Jogs, Incline, Decline

Automation

Integrators

Material Handling

E-Commerce

Packaging

Medical

Pharmaceutical

Conveyor Insights

Dorner Helps Breathe Medical with Flexible Conveyor System

Dorner provided Breathe Medical Manufacturing with an extensive FlexMove conveyor system for their new mask manufacturing facility.

Adding Efficiency and Saving Space in Medical Device Production

This custom FlexMove system was designed to carefully handle delicate medical devices while maintaining a small footprint.

Flexible Tote Transport System for Mail Order Pharmaceuticals

Dorner has helped build numerous automated prescription processing conveyor systems for mail-order pharmacies.

Contact the Conveyor Experts!

Our team is standing by to answer any questions you may have and help you improve your production line with a FlexMove conveyor system.

Solutions

Complete conveyor systems shipped in sub-assemblies for fast and easy installation

Modules

Accessory modules designed to enhance the abilities of FlexMove conveyors.

Components

Aluminum and Stainless conveyor components for complete flexibility in layout and design

Ready for a New FlexMove Conveyor System?

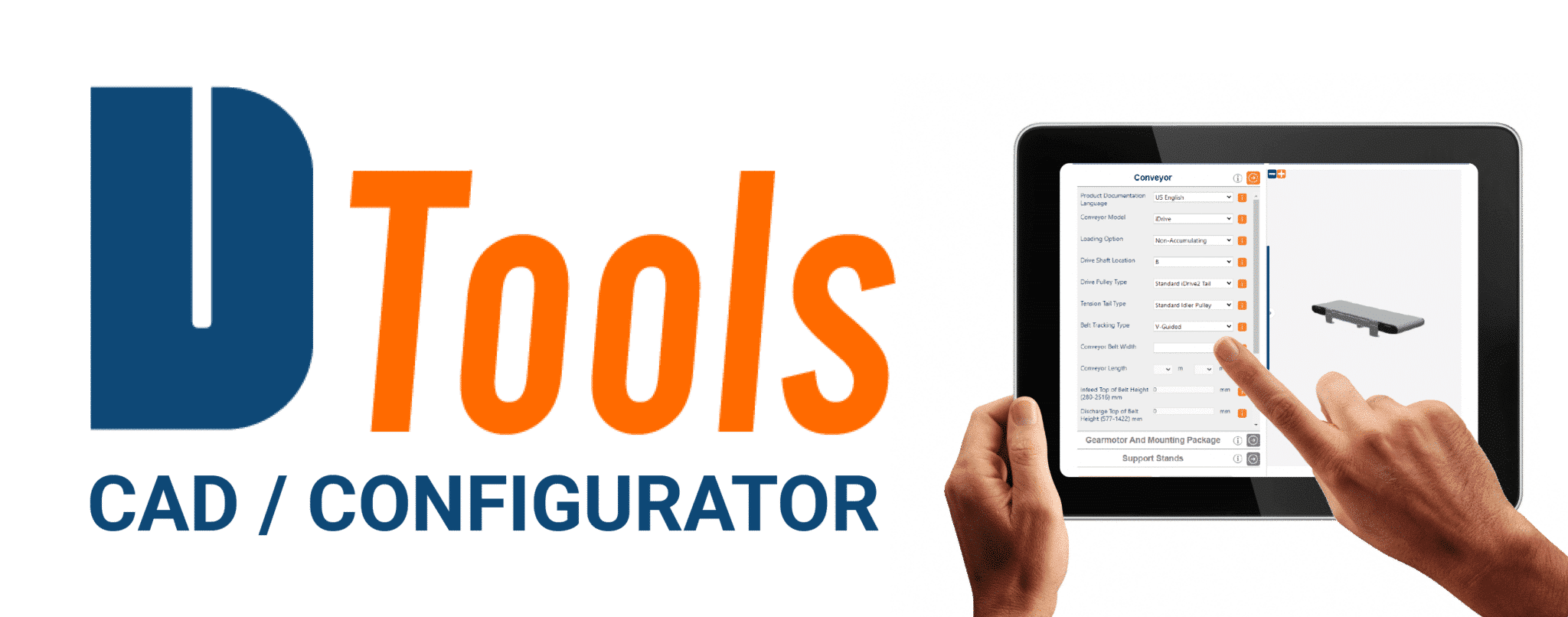

Sign up for DTools to start configuring your custom conveyor.

OR

Contact us for a no-obligations quote!

Create your own custom conveyor with Dorner’s industry-leading CAD/Configurator software. With DTools, designing a conveyor that meets your specific application is quick and easy. Submit a request for complete custom systems or replacement parts for your existing conveyor, and get a free quote and CAD design fast!

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy